sheet metal drawing example

Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching cutting stamping and bending. 37A part will be drawn positioned.

Sheet Metal Drawing Sheet Sheet Metal Drawing Drawing Sheet Sheet Metal

Sheet Metal Shop Dwg - Rooftop.

. Select the BLAH_SHEET METALipt option. Sheet metal parts are known for their durability which makes them great for end use applications. Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula.

Pots and pans for cooking containers sinks automobile parts such as panels and gas tanks are among a few of the items manufactured by sheet metal deep drawing. Application of sheet- metal working. The numbers in the red circles correspond to the following.

Enter 1mm in the Thickness field. I want stress relief radii. 41 OPENING A NEW SHEET METAL PART Click the new icon or go to the file menu and select new.

The Sheet Metal Parameters dialog box is displayed. Sheet metal is widely used for numerous industrial and non-industrial applications including. F YS UTS2 A.

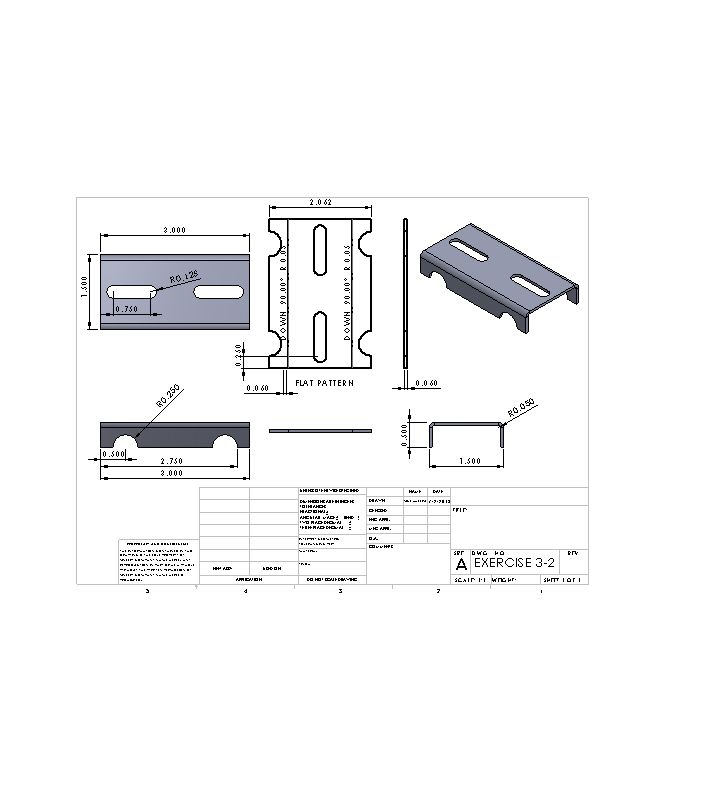

Figure 1 shows a sheet metal mounting structure example downloaded from the National Institute of Standards and Technology NIST website. I am apply my dimensions carefully so that they are unambiguous. Click the Sheet Metal Parameters icon.

Touch device users explore by touch or with swipe gestures. D 25T R see below The height can be less but it required secondary operations and is far more costly. Deep Drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces.

11Save the drawing in the same folder as the part with the PART NUMBER as the name of the drawing file. Jun 8 2019 - Explore H G Raghunandans board Sheet metal drawing on Pinterest. This process is sometimes called drawing and is not to be confused with the bulk.

The template can include customized information such as material cost and thicknesses cost of manufacturing operations and manufacturing setup costs. When autocomplete results are available use up and down arrows to review and enter to select. Flatten Length Sum of all sides Bend Deduction x number of bends The Sum of all Sides 20 36 72 45 45 72 36 20 301 mm Flatten Length 301 mm 300 mm x 6 283 mm After determining the flatten length compare this value with the flatten length obtained from the flat pattern.

See more ideas about sheet metal drawing sheet metal isometric drawing. Multi-model Sheet Metal Drawing. New File Dialogue 42 SETTING UP SHEET METAL STYLES.

I designed a sheet metal as a example part on Siemens NX and I created technical drawing for you you can get models from here. To improve the communication clarity and reduce the 2D drawing maintenance overhead many manufacturers are looking for ways to communicate sheet metal product and manufacturing information PMI in 3D using. Sheet Metal Shop Dwg - Plan View.

Including a BOM has many benefits. Sheet Metal Shop Dwg - Vertical Duct. Base Place ews Annotate Tools Manage AutoclE5k Inventor Professional 2010 View Environments Vault Get Started Add-Ins Nailboard Connector - EDUCATIONAL INSTITUTION VERSION s metal Auxiliary Draft area k Break Out Slice Crop Projected Section Detail Create Overlay Open Libraries Horizontal Create.

I see including a table with one row as drafting clutter. Body panels bumpers doors chassis trim parts brackets etc. I systematrically specify bend radii on my drawings and I include details showing what the bend corners look like before bending.

For example on a sheet metal part you may write All bends are 90 unless otherwise stated Dont write anything in the bottom right corner. 3D CAD files are converted into machine code which controls a machine to precisely cut and form the sheets into the final part. 36All views on the drawing must have at least one dimension associated to them except for isometric view.

In the example shown in Figure 1 we have captive fasteners installed in a sheet metal part. I dont put any standard notes on my sheet metal drawings. In following days Iill upload tutorial video about this part by using NX.

I do not put a BOM table on the drawing if the product has only one component. 35All views must be spaced equally. My youtube channel.

You will be presented with the Blah template dialogue see Figure 4-1. Defining the Sheet Metal Parameters This task shows you how to configure the sheet metal parameters. Model two of the multi-model drawing.

Enter 5mm in the Default Bend Radius field. In this tutorial video we will learn how to sketch sheet metal drawings in Solidworks with the help of sheet metal toolsPlease subscribe our channel for mor. Sheet Metal Shop Drawings.

Search Sheet Metal Templates in the SOLIDWORKS Knowledge Base. This duct is made from a 5 foot 60 inch coil width and the difference is from the joint. 34A projected view that is positioned on the next drawing sheet must have a name VIEW X and an arrow needs to be added from the view it was projected from on the first sheet.

Sample Sheet Metal Shop Drawings. Select the Bend Extremities tab. I have read up on and taken a course on the ASME Y145M-1994 standard.

1 Duct Size Joint Length This shows that the rectangular duct that is 70 x 18 in size is 56 14 in length. Deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Sheet Metal Shop Dwg - Sections.

We can consider a component as the deep-drawn if the depth of the drawn. 60 coil width 3 34 joint 1-58. F stretch forming force lbs YS material yield strength psi UTS ultimate tensile strength of the material psi A Cross-sectional area of the workpiece in2 Forces needed to bend sheet metal.

If SolidWorks tells you to save the part when you save the drawing say OK. Fuselages wings body panels trim parts etc. Because multiple components are in the product a bill of materials is needed.

The sheet metal template contains the procedures you or your sheet metal manufacturing supplier use to manufacture the part. Sheet Metal Shop Drawings. Roofing home building and structural applications.

Sheet Metal Shop Dwg - Details.

학습자료 3d 연습도면 3d모델링 연습도면 1020 네이버 블로그 Autocad Isometric Drawing Autocad Drawing Technical Drawing

Chassis Drawing Sheet Sheet Metal Drawing Sheet Metal Drawing Sheet

Electrical Box Flat Pattern Drawing Sheet Sheet Metal Drawing Drawing Sheet Sheet Metal

Esercizio 54 Sheet Metal Drawing Mechanical Design Technical Drawing

Solidworks 2013 Sheet Metal Metal Furniture Design Metal Sheet Design Sheet Metal Shop

Kết Quả Hinh ảnh Cho Engineering Drawing Engineering Mechanics Statics 14th Edition Engineering Mechanics Statics Sheet Metal Fabrication

Using Solidworks Sheet Metal Functionality Create A B Size Drawing Sheet Metal Drawing Technical Drawing Mechanical Engineering Design

I Want Sheet Metal Part Drawings To Practice Iam Not Able To Get From Google Can Anyone Pls Help Me Grabcad Que Sheet Metal Drawing Sheet Metal Drawing Sheet

Structural Engineering Services India Steel Structural Detailing Sheet Metal Drawing Sheet Metal Fabrication Metal Fabrication

Pin By Ibrahim Unsal On Technische Tekeningen Sheet Metal Drawing Drawing Sheet Sheet Metal

This Drawing May Differ From The Actual Product Drawing An Educational Example For Studen Mechanical Engineering Design Solidworks Tutorial Mechanical Design

Teknik Resim Cizim Ornekleri Sheet Metal Drawing Sheet Metal Solidworks Tutorial

China Acculine Sheet Metal Deep Drawing Quality Control Inspection Report Example Cs080003 By Acculine Precision Manufacturin Deep Drawing Sheet Metal Drawings

Construction Set For Sheet Metal Scale Model Making Sheet Metal Drawing Solidworks Tutorial Sheet Metal

Pin By Durga Munivelu On 3d Modeling Practice Autocad Isometric Drawing Isometric Drawing Technical Drawing